LYS Polychem Blog

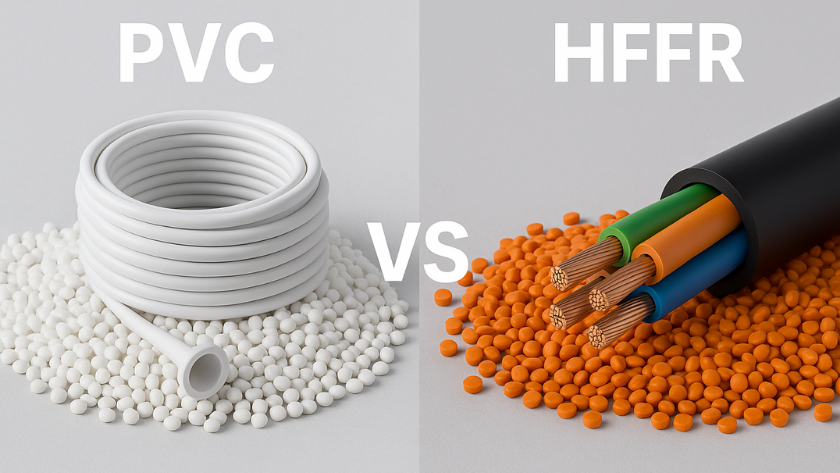

PVC and HFFR: Which Material is More Effective in Which Application?

From cable insulation to construction materials, the performance of plastic-based materials used in modern production processes is becoming more and more important every day. Especially in today's world where fire safety and environmental standards are on the rise, the question "PVC or HFFR?" has become a common decision point for many manufacturers and engineers.

In this article, you can find answers to questions such as “what is the difference between PVC and HFFR, which material is more advantageous in which application?”. Without drowning in technical details, we will discuss the strengths and weaknesses of both materials in simple language.

What is PVC? Where is it Used?

PVC (Polyvinyl Chloride) is a thermoplastic that has been widely used in various sectors for many years. Its ability to be produced in flexible or rigid forms, its low cost and easy processability make PVC an attractive option in many fields. It is especially preferred for applications such as window profiles, pipes, floor coverings and cable insulation.

However, PVC's fire behavior poses some disadvantages. When exposed to high temperatures, it releases toxic gases such as hydrogen chloride and generates dense smoke, creating a serious risk for indoor areas. For this reason, as fire safety regulations have increased in recent years, there has been an increased tendency towards alternative materials in some areas.

What is HFFR? What are its Advantages?

HFFR (Halogen-Free Flame Retardant) materials, as the name suggests, consist of compounds that do not contain halogen and do not release harmful gases into the environment during a fire.

The biggest advantage of HFFR is its high resistance to fire and low smoke density. In addition, since it does not emit toxic gases, it offers a safe option in areas with high human density such as hospitals, schools, shopping centers and airports. Thanks to these features, HFFR comes to mind when it comes to flame retardant cable materials.

What are the Differences Between PVC Compound and HFFR?

The differences between PVC and HFFR granules are not only limited to fire resistance. Issues such as workability, cost, environmental impact and mechanical performance should also be taken into account when making a decision between the two. If we compare them in detail;

PVC granular materials can be ideal for economical production and areas where the risk in terms of fire safety is low. HFFR, on the other hand, stands out in applications where safety is a high priority.

Which Material Should be Preferred Where?

Comparing PVC and HFFR, there are application areas where both materials stand out. For example;

PVC is frequently preferred in the construction industry, piping systems, floor coverings and products where outdoor resistance is required. It's economical and easily processable so that features provide a great advantage.

HFFR compound is used in cable insulation and sheathing applications, especially in fire resistant cabling systems. It offers ideal solutions in terms of safety in areas such as subway lines, data centers and high-rise buildings.

The effectiveness of the materials depends entirely on the intended use and the needs of the field of application.

PVC or HFFR: Which is Preferred?

PVC and HFFR are two strong materials of choice for different applications. If your application emphasizes low cost and flexible production, PVC compound is reliable. But if criteria such as fire safety, environmental impact and toxic gas emissions are paramount, working with HFFR materials can be much more advantageous in the long run.

While PVC is still used in open spaces or low-risk applications, HFFR stands out in buildings that require high safety standards. When factors such as fire resistance, smoke density and toxicity are taken into account, preferences become clear according to needs. In addition, although the cost and processability of HFFR compounds may seem like a disadvantage, this difference decreases with current technologies. Especially as copper prices rise, the impact of the insulation material on the total cost of the cable decreases. Therefore, HFFR compounds are technically and economically more accessible.

LYS Polychem aims to offer the most suitable solution with its wide range of products and technical support services in both material groups. You can contact LYS Polychem to get information about the compounds suitable for your needs and to work with a reliable supplier.